FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

Choosing the right wood sanding disc for grinder can significantly impact your woodworking projects. Industry expert Mark Davidson states, “The right disc makes the difference between a smooth finish and frustration.” This emphasizes the need for careful selection.

A wood sanding disc for grinder varies in grit levels and materials. It's crucial to understand these options to achieve the desired finish. Many users overlook their specific project needs. Some discs may wear too quickly, leading to uneven surfaces.

Additionally, choosing the wrong disc might cause damage to your wood. Taking time to reflect on past experiences can guide better choices. Remember, the right wood sanding disc for grinder is not just about cost; it’s about quality and purpose.

Wood sanding discs come in various types and materials. Understanding these differences is essential for effective sanding. There are fiber discs, zirconia discs, and aluminum oxide discs. Fiber discs are durable and good for heavy stock removal. Zirconia discs are ideal for wood, metal, and fiberglass. Aluminum oxide discs work well for finishing.

When selecting a disc, consider the material of your workpiece. Hardwoods require tougher discs. Softwoods may need gentler options. The grit of the disc also matters. Finer grits provide smoother finishes. Coarser grits are suitable for faster material removal.

Tips: Always test a disc on scrap material first. This helps you gauge its effectiveness. Wearing protective gear is crucial. Don’t overlook safety while sanding. Ensure your workspace is clean. Dust can hinder your results and pose health risks.

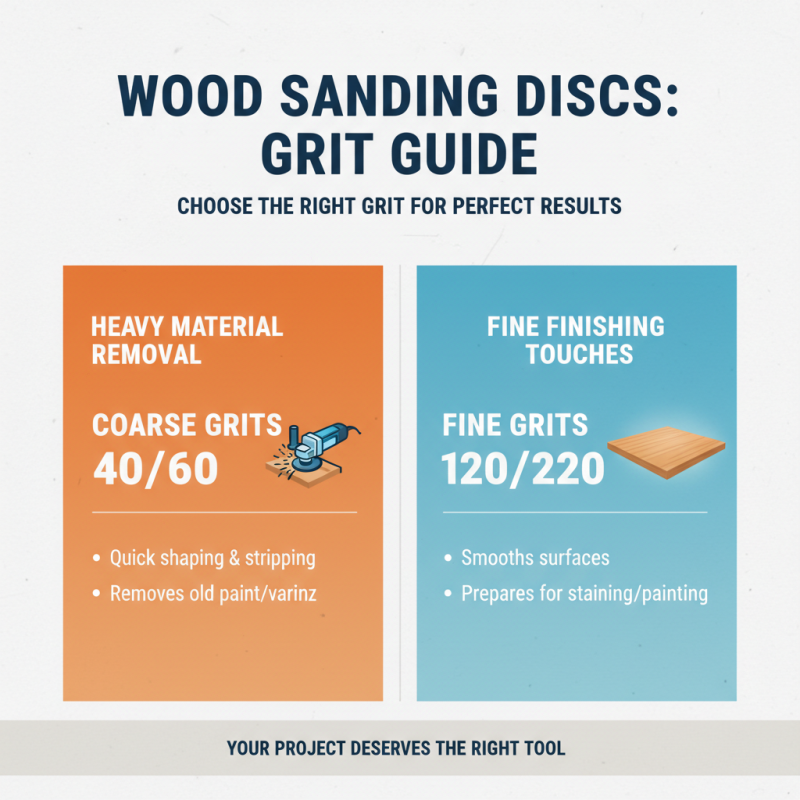

When selecting wood sanding discs for your grinder, it's crucial to consider key features. The grit size is vital. Coarser grits, like 40 or 60, are best for heavy material removal. Conversely, finer grits, such as 120 or 220, work well for finishing touches. Choosing the right grit affects your project's outcome significantly.

Another factor is the disc material. Aluminum oxide is common for versatility. On the other hand, ceramic might last longer on tough surfaces. Each material has its strengths and weaknesses. Sometimes, experimenting is necessary to find what suits your needs best.

Compatibility with your grinder is also crucial. Ensure the sanding disc fits your model. An incorrect fit can lead to poor performance. It's often overlooked. Users might grab a disc and later discover it doesn't attach properly. Checking specifications beforehand can save frustration. Remember, not every choice will be perfect. Some trial and error is part of the process.

Choosing the right grit for your wood sanding disc is crucial for achieving the desired finish. Different projects require different levels of abrasiveness. For rough surfaces, start with a lower grit. Grits around 60 to 80 are effective for quick material removal. They can smooth rough edges and prepare surfaces for finer sanding.

When working on finer details, a higher grit is essential. Grits of 150 to 220 help create a smooth finish without visible scratches. They are perfect for finishing tasks. It's important to remember that the right grit can vary depending on the wood type. Softer woods may need less aggressive sanding, while harder woods might require a bit more effort.

Sometimes, finding the perfect grit is trial and error. You might end up with an uneven surface if you rush the process. It's worthwhile to test different grits on scrap pieces before starting your main project. Patience in this step can lead to a significant improvement in the final outcome. Adjusting your technique based on the results is key to mastering wood sanding.

When selecting a sanding disc for your grinder, the type of attachment can significantly influence your project.

Hook-and-loop discs are popular for their convenience. They allow for quick changes,

minimizing downtime. A recent industry report reveals that 65% of professional woodworkers

prefer hook-and-loop systems for their efficiency in projects requiring multiple grit changes.

However, adhesive discs have their own advantages. They offer a secure bond that reduces the risk of slippage.

This stability makes them suitable for heavy-duty sanding tasks. While they may involve a longer change process,

many users argue that the result justifies the time spent. Data shows that 30% of users indicated fewer defects

when using adhesive discs on challenging surfaces.

Ultimately, your choice may depend on the specific job requirements.

Hook-and-loop systems shine in versatility, while adhesive discs excel in consistency.

Understanding the pros and cons of each can lead to more successful sanding outcomes.

Like many decisions in woodworking, choosing the right disc is about balance.

Using sanding discs on grinders requires careful technique and attention to detail. The right sanding disc can significantly enhance your woodworking project. Research indicates that the efficiency of sanding can increase by up to 30% with the proper disc selection. Many users underestimate the importance of grit size. Coarse grits work for heavy material removal, while fine grits are for finishing touches.

When applying pressure, it’s crucial to avoid excessive force. This can lead to uneven surfaces. Reports show that over 40% of users apply too much pressure, resulting in premature disc wear. Instead, allow the disc to do the work. A light, steady pressure often leads to smoother finishes. Be mindful of the angle you hold the grinder. An incorrect angle can gouge the wood and ruin your progress.

Environmental factors also play a role. Dust buildup can clog sanding discs, reducing their effectiveness. Regularly cleaning the work area and the disc will minimize this issue. Consider switching discs frequently during long tasks. Overheating can occur when one disc is overused. Surveys have identified that more than 25% of users face overheating problems. Taking these small steps can lead to significantly better outcomes.

| Disc Type | Grit Size | Material | Best For | Lifespan |

|---|---|---|---|---|

| Aluminum Oxide | 60 - 120 | Aluminum Oxide | General Wood Sanding | Moderate |

| Silicon Carbide | 120 - 220 | Silicon Carbide | Sanding Softwoods | Long |

| Zirconia | 24 - 60 | Zirconia Alumina | Heavy Duty Sanding | Very Long |

| Garnet | 180 - 320 | Natural Garnet | Finishing Work | Short |

| Non-Woven | N/A | Synthetic | Surface Preparation | Moderate |