FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

Choosing the right manufacturer for a 16mm drill bit is essential for both professionals and DIY enthusiasts seeking efficiency and precision in their projects. With the global market for power tools projected to reach $41.40 billion by 2027, the demand for high-quality drill bits, particularly in the 16mm size, has never been greater.

According to industry reports, a significant portion of this market growth is attributed to advancements in material technology and manufacturing processes, which directly influence the performance and durability of drill bits. Selecting a reputable manufacturer not only ensures superior technical specifications but also enhances operational efficiency, potentially leading to cost savings in both materials and labor. Therefore, understanding the key attributes of a 16mm drill bit, such as cutting speed, material composition, and design features, is crucial for making informed purchasing decisions.

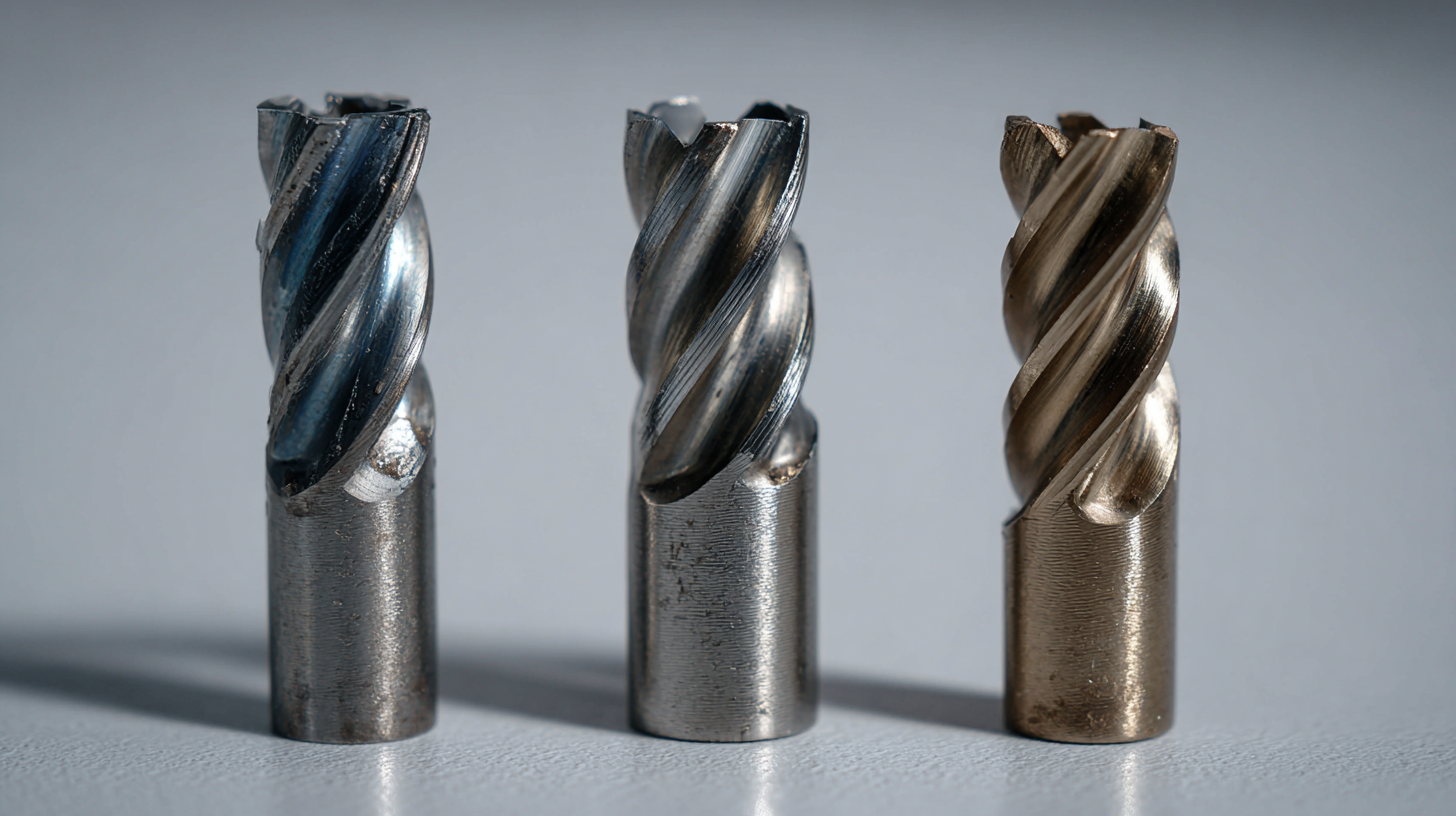

When choosing a 16mm drill bit, the material it’s made from plays a crucial role in its performance and longevity. High-quality steel, particularly high-speed steel (HSS) and cobalt steel, stands out as the most suitable materials for manufacturing durable drill bits. According to a report by Grand View Research, the global drill bit market is anticipated to reach USD 16.7 billion by 2025, driven by the increasing demand for efficient drilling tools. This emphasizes the industry's focus on enhancing manufacturing quality to meet rigorous demands.

The hardness and tensile strength of steel greatly influence the efficiency of a drill bit. HSS drill bits, for example, are known for their ability to withstand high temperatures and resist wear, making them ideal for drilling through hard materials. A study published in the Journal of Materials Processing Technology indicates that drill bits manufactured from high-quality steel can outperform lower-grade alternatives by more than 30% in terms of lifespan and drilling speed. By investing in a drill bit made from superior materials, professionals can ensure optimal performance and cost-effectiveness over time.

When selecting the right manufacturer for the best 16mm drill bit, evaluating the manufacturer's reputation is paramount. Key metrics to consider include product quality, customer service, and production reliability. A reputable manufacturer should have a history of delivering high-performance drill bits that withstand rigorous drilling conditions. Checking reviews and testimonials can provide insights into user experiences, helping you gauge the overall satisfaction of previous customers.

In addition to customer feedback, industry standards play a crucial role in assessing a manufacturer’s credibility. Certifications such as ISO and ANSI not only ensure that the products meet specific quality benchmarks but also indicate the manufacturer's commitment to continuous improvement. It is advisable to choose manufacturers that adhere to these standards, as they often invest in advanced technology and skilled craftsmanship. By carefully evaluating both the manufacturer's reputation and adherence to industry standards, you can make a more informed decision, ultimately leading to better performance and reliability in your drilling tasks.

When selecting the ideal 16mm drill bit, understanding the significance of tolerance levels in precision engineering becomes crucial for optimal performance. Tolerance refers to the allowable deviation from a specified dimension, and for drill bits, even the slightest variation can significantly affect the drilling process. High-quality manufacturers maintain strict tolerance levels, ensuring that their drill bits produce accurate holes with minimal friction and wear. This precision not only enhances the efficiency of drilling operations but also extends the lifespan of the tool.

Moreover, the impact of tolerance on drill bit performance extends beyond mere accuracy. In applications requiring a snug fit, such as in construction or machinery assembly, a drill bit with tighter tolerances will create cleaner, more precise holes, reducing the risk of damage to the material being worked on. Conversely, looser tolerances can lead to increased wobble and poor finishing, which may necessitate additional machining or fitting time. Therefore, assessing a manufacturer’s commitment to precision engineering is essential when choosing the right drill bit to ensure both performance and reliability in various applications.

When it comes to selecting the best 16mm drill bit, the balance between cost and quality is a critical factor for both DIY enthusiasts and professionals. According to a report by the Global Industrial Tool Market, the price range for high-quality 16mm drill bits typically falls between $10 and $50, depending on the manufacturer and materials used. Tungsten carbide bits tend to be on the higher end of this spectrum, known for their durability and ability to drill through tougher materials, while high-speed steel bits might be more affordable but may require more frequent replacements.

In analyzing various manufacturers, it becomes clear that investing in a reputable brand can lead to long-term savings. The same report indicates that while cheaper drill bits might save money upfront, they often result in lower efficiency and more frequent failures. For instance, manufacturers like Bosch and DeWalt, who are recognized for their commitment to quality, often charge a premium but provide products that last 3-5 times longer than lesser-known brands. This consideration of cost versus quality is crucial for achieving the best performance in any drilling project, ensuring that your investment yields substantial returns in terms of time and productivity.

When it comes to selecting the best 16mm drill bit manufacturer, customer reviews and feedback are invaluable resources. User experiences provide insights that go far beyond product specifications, offering real-world context about durability, performance, and overall satisfaction. By delving into reviews, potential buyers can identify patterns of quality and service that may not be apparent from promotional materials. Engaging with these experiences enables shoppers to make informed decisions that align with their specific needs.

Moreover, leveraging user feedback helps highlight any recurring issues that may not be clear from technical descriptions. Customers often share their challenges and how well a manufacturer addressed them, shedding light on the responsiveness and support provided by the brand. This information can be crucial for anyone looking to invest in drill bits, as it not only determines the best quality but also the reliability of customer service. Making an informed choice based on genuine user experiences can significantly enhance the purchasing process, ultimately leading to a more satisfactory outcome.