FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

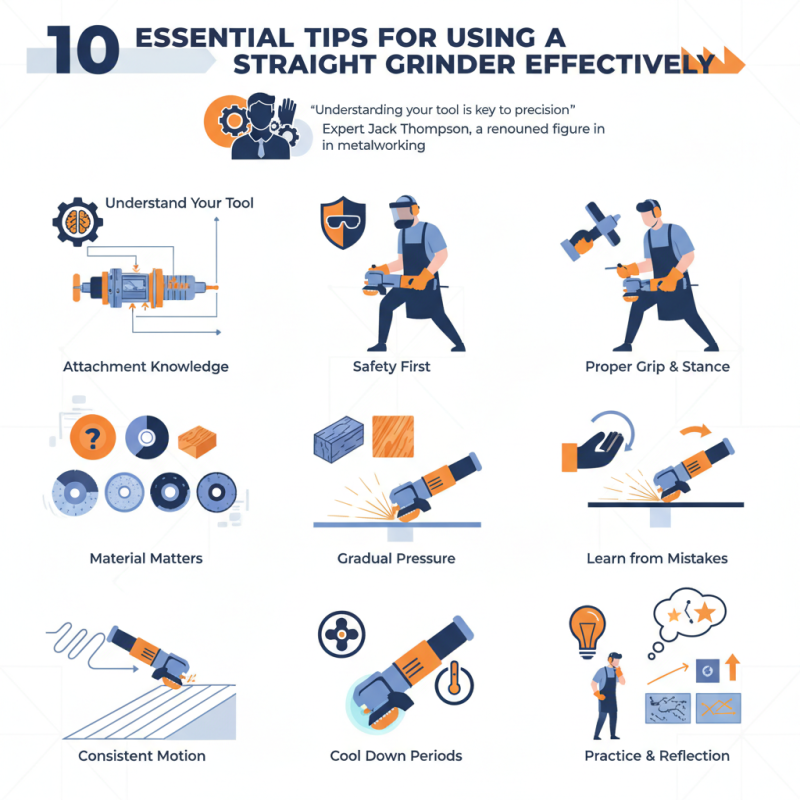

When it comes to mastering the use of a Straight Grinder, practical knowledge is essential. Expert Jack Thompson, a renowned figure in metalworking, shares valuable insights. He once said, “Understanding your tool is key to precision.” This statement highlights the importance of familiarity with the Straight Grinder.

A Straight Grinder can be a versatile tool in any workshop. It can cut, grind, and polish materials effectively. However, improper use can lead to poor results or even injuries. A careful approach is crucial. Pay attention to safety measures. Proper grip and stance matter. Familiarize yourself with the tool's different attachments, as they serve distinct purposes.

The journey of becoming proficient with a Straight Grinder involves reflection and continuous learning. Mistakes made along the way can offer valuable lessons. Each task performed with the tool can reveal areas for improvement. Take time to analyze your technique. This self-awareness can lead to better performance and greater confidence in your skills.

Choosing the right straight grinder can significantly affect your project’s outcome. Consider the power and speed of the tool. A higher RPM might be essential for tougher materials, but it can also lead to mistakes. Too much speed can cause overheating. It’s vital to match the grinder’s capabilities to your tasks.

Another factor is the weight and design of the grinder. A heavier tool can be harder to control, especially during prolonged use. Light models may be handy, but they can lack power. Test different options. You might discover that comfort is as crucial as performance.

Attachments and accessories should align with your needs. Choose ones that enhance versatility without overcomplicating your setup. Having too many options can lead to confusion. Sometimes, less is more. Reflect on your projects and needs. It’s okay to feel uncertain. Selecting the right straight grinder takes time and experimentation. Adjust as you learn.

When using a straight grinder, understanding attachments is crucial. Different accessories can significantly enhance performance. For instance, cutting wheels are perfect for metalwork. They create clean cuts and are efficient for various materials. In contrast, flap discs are excellent for smoothing surfaces. They provide a finish that is hard to achieve with standard grinding wheels.

Tip: Always choose the right attachment for the task. Using an incorrect tool can lead to uneven results. A report by the American National Standards Institute states that over 30% of tool-related errors arise from improper usage. Therefore, familiarizing yourself with each attachment's purpose is essential.

Another important accessory is the backing pad. It offers stability when polishing or sanding. A good backing pad reduces vibrations and helps maintain control over the grinder. However, neglecting to check its condition can lead to issues. Worn-out pads can cause uneven wear and damage your workpiece.

Tip: Regularly inspect your attachments. This simple practice can improve both safety and efficiency. Even small wear can lead to larger problems down the line. Addressing these issues promptly is key to effective grinder usage.

Using a straight grinder can be dangerous if proper safety precautions are not followed. According to a report from the Occupational Safety and Health Administration (OSHA), grinder-related injuries account for about 10% of all workplace accidents in manufacturing. This statistic highlights the importance of safety measures and awareness.

Before starting work, inspect the grinder for any damage. Check the power cord, grinding wheel, and protective guards. A damaged tool can lead to severe injuries. Wearing personal protective equipment (PPE) like safety goggles and gloves is essential. The American National Standards Institute (ANSI) emphasizes that 70% of head injuries from grinding could be prevented with proper eye protection.

Always maintain a firm grip on the grinder and choose the right wheel for the job. Operators should be trained to recognize signs of wear on the grinder. Failing to replace a worn wheel could lead to breakage and accidents. Never bypass safety features, even if it seems tedious. Engaging in unsafe practices often leads to regret and injury. Awareness and diligence can create a safer working environment.

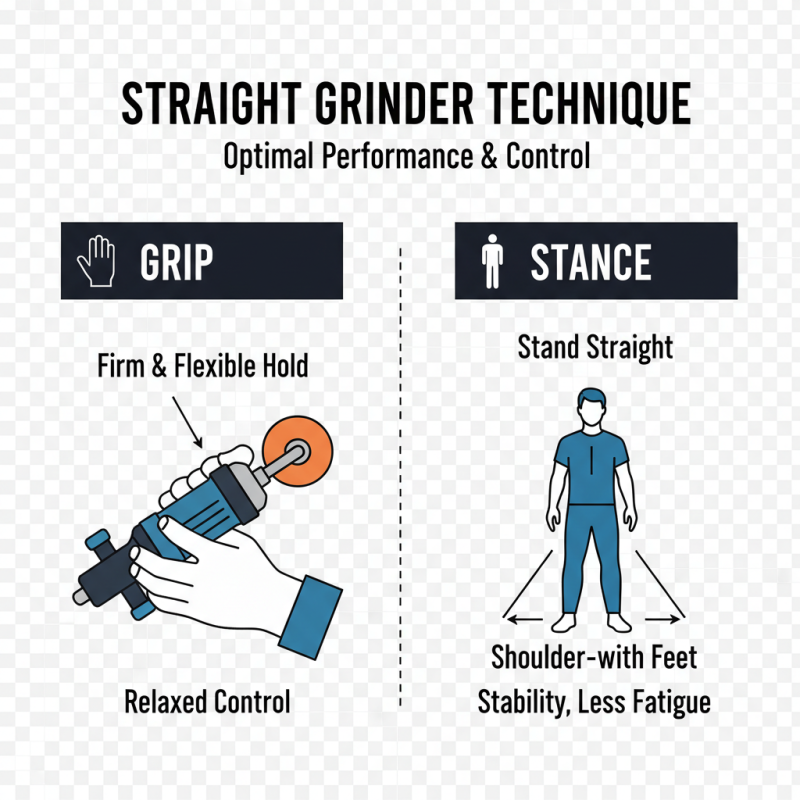

When using a straight grinder, achieving optimal performance requires skill and attention to detail. Adjust your grip. It should be firm yet flexible. A relaxed hold helps control the tool better. Your stance matters. Stand straight, feet shoulder-width apart. This gives you stability, reducing fatigue during operation.

Mastering the right technique is key. Always maintain the proper angle when grinding. Too steep, and you risk damaging the material. Too shallow, and your effort goes to waste. Use light pressure. Pushing too hard can overheat the bit and lead to poor results. Remember our human tendency to rush. This can result in mistakes and suboptimal finishes.

Routine checks on your equipment are vital. A worn-out tool can create inefficiencies. It’s frustrating when an unexpected snag occurs mid-task. Always inspect your grinder before starting. Also, make adjustments based on the job at hand. Different materials may need varied approaches. Reflect on your experiences—what worked, what didn't. Learning from each project will refine your skills.

Proper maintenance is crucial for the longevity of a straight grinder. Regular cleaning is essential. After every use, wipe down the body and the rotating parts. Dust and debris can accumulate quickly. This buildup can affect performance and lead to malfunctions. Be sure to check the air filters as well. Dirty filters can hinder airflow, overheating the tool.

Lubrication is another critical aspect to consider. Apply the right type of lubricant to the bearings periodically. A well-oiled tool runs smoother and lasts longer. However, it's easy to over-lubricate, which can create a mess and attract more dust. Always follow the manufacturer's guidelines on lubrication amounts. It’s essential to reflect on routine checks. Simple inspections can reveal worn parts before they cause significant issues. Consider setting reminders for maintenance tasks to avoid forgetfulness.