FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

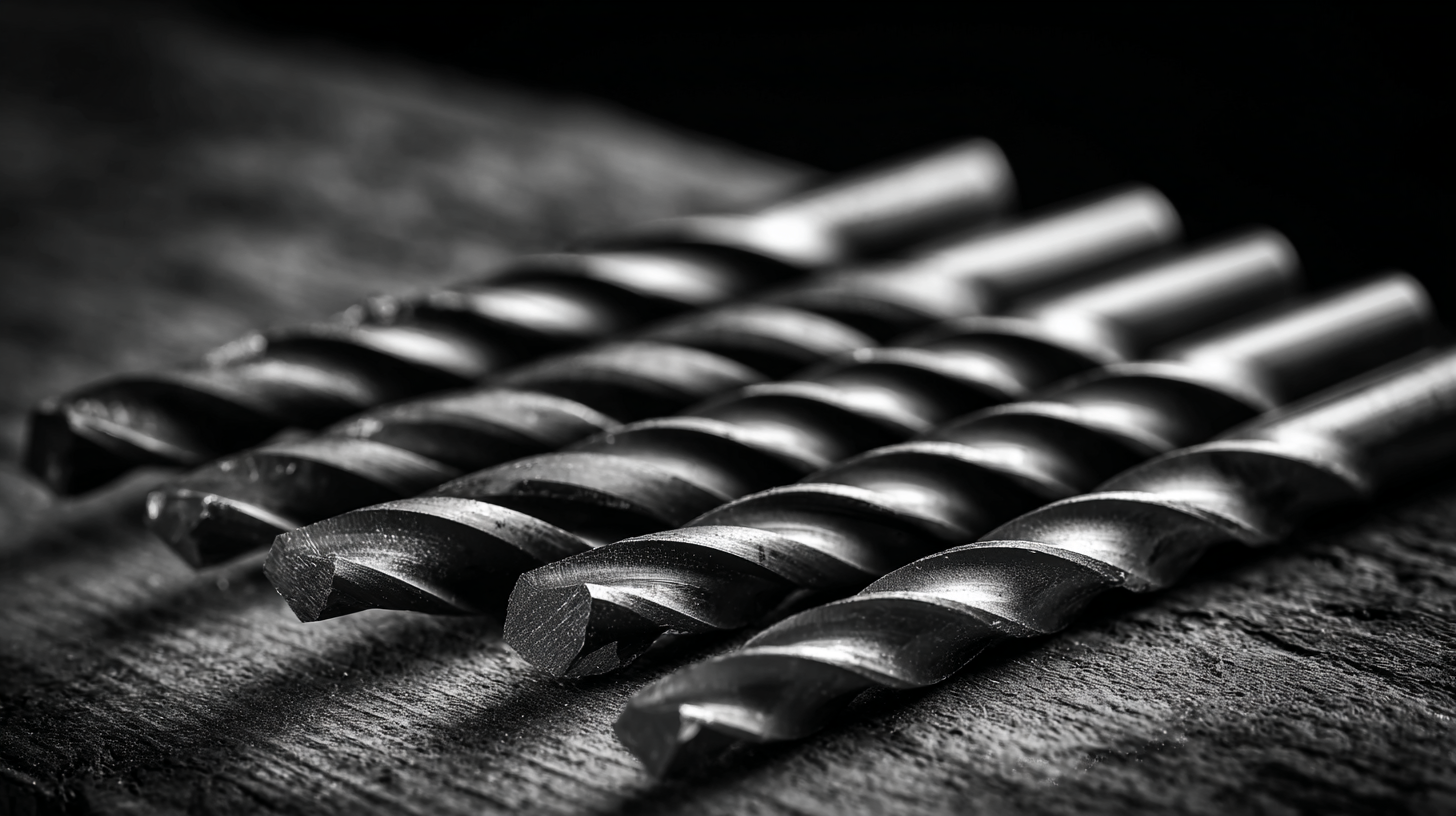

In the realm of metalworking, precision and efficiency are paramount, and the choice of tools directly impacts these factors. Among the various tools available, "Carbide Bits for Metal" have emerged as a cornerstone for achieving high-quality outcomes in machining and fabrication. According to a recent industry report by Grand View Research, the global metalworking tools market is expected to reach USD 96.73 billion by 2025, driven by advancements in manufacturing technologies and the increasing demand for efficient machining processes. Carbide bits, known for their durability and ability to maintain sharp cutting edges under extreme conditions, significantly enhance productivity and precision in metalworking tasks. As metalworking professionals seek to optimize their workflows, understanding the various applications and benefits of carbide bits becomes essential for staying competitive in an ever-evolving industry.

Carbide bits play a crucial role in enhancing precision and efficiency in metalworking. Unlike traditional steel bits, carbide bits are made from tungsten carbide, which makes them much harder and more durable. According to a recent industry report from the Metalworking Technology Council, tools made from carbide can maintain cutting edges up to 5 times longer than those made from high-speed steel, significantly reducing downtime for tool changes and maintenance costs. This superior hardness enables carbide bits to cut through tough metals like stainless steel and titanium, making them ideal for high-performance applications.

When choosing carbide bits, it's essential to understand their key features, such as the various coatings available. TiN (titanium nitride) and TiAlN (titanium aluminum nitride) coatings can enhance the bit's performance by reducing friction and extending tool life. A study from the Journal of Manufacturing Processes found that coated carbide tools could increase cutting speeds by up to 30%, further boosting productivity.

**Tips:** When selecting carbide bits, consider the type of metal you will be working with and choose a bit with an appropriate coating for the job. Regularly cleaning the bits can also prevent buildup, allowing for smoother cuts and prolonged tool life. Always ensure that your machine settings optimize the capabilities of carbide bits to achieve the best results.

| Feature | Description | Advantages | Applications |

|---|---|---|---|

| Material Composition | Made from tungsten carbide for durability and hardness. | High wear resistance, long lifespan. | Metal machining, drilling, milling. |

| Cutting Edge Design | Optimized geometry for faster cutting. | Improved efficiency and precision. | Precision machining, CNC operations. |

| Heat Resistance | Can withstand high temperatures without losing hardness. | Reduces the need for frequent tool changes. | Heavy-duty machining applications. |

| Versatility | Suitable for various materials, including hard metals. | Can be used in a wide range of metalworking tasks. | Aerospace, automotive, and manufacturing industries. |

| Cost Efficiency | Higher initial cost offset by longevity and reduced downtime. | Lower overall operational costs over time. | Manufacturing processes with high production rates. |

When it comes to precision metal cutting and shaping, the right type of carbide bit can significantly enhance efficiency and accuracy in metalworking. Among the top contenders, tungsten carbide rotary burrs stand out due to their durability and versatility. These double-cut diamond burrs, typically available in various diameters such as 6mm, are designed to handle both wood carving and metal polishing, making them an indispensable tool in any metalworker's arsenal.

Additionally, the market for carbide cutting tools is evolving, with coated carbide tools dominating at 77.3% of the market share in 2024. This highlights the growing preference for tools that offer improved performance and longevity, which are crucial for high-speed applications. As the industry continues to innovate, selecting the right carbide bit—whether for shaping, cutting, or machining—will ultimately determine the quality of the finished product and the efficiency of the processes involved.

When choosing the best carbide bit for your metalworking projects, it's essential to consider the specific materials you will be working with. Carbide bits are known for their exceptional hardness and wear resistance, making them ideal for drilling through tough materials like steel and aluminum. Always opt for bits designed specifically for metal, as they will provide the precision and efficiency required for high-quality results.

Tips: Look for carbide bits that feature optimized flute designs — this will ensure effective chip removal and minimize friction during drilling. Additionally, consider the coating of the bits. Some coatings enhance the durability and reduce overheating, which can prolong the life of your tools.

Moreover, testing various options on different metals can help you make an informed decision. For instance, experience has shown that bits designed for hardened steel outperform standard bits when it comes to precision and efficiency. Make sure to check performance reviews and select bits that best match your project requirements for optimal outcomes.

Maintaining carbide bits is crucial for ensuring their longevity and optimal performance in metalworking applications. One essential tip is to always use the appropriate speed and feed rates when machining. Using speeds that are too high or too low can lead to premature wear and tear on the carbide bits. Additionally, selecting the right bit for the specific material being machined significantly impacts both the life of the tool and the quality of the finish.

Regular maintenance also plays a key role in prolonging the life of carbide bits. Cleaning the bits after each use to remove metal shavings and debris helps prevent build-up that can affect their cutting efficiency. It's also advisable to inspect the bits for any signs of chipping or wear periodically. If minor damage is detected, resharpening the bits can restore their cutting capabilities, further extending their usefulness. By implementing these maintenance strategies, metalworkers can enhance the performance of their carbide bits and ensure they remain effective for a long time.

When it comes to metalworking, selecting the right cutting tool is crucial for achieving precision and efficiency. Carbide bits have emerged as a top choice among professionals, but how do they compare to other metal cutting tools? Carbide bits are known for their durability and ability to withstand high temperatures, making them ideal for tough materials. In contrast, high-speed steel (HSS) bits may offer lower initial costs but typically wear out faster and require more frequent replacements.

Tips: When choosing between carbide bits and HSS tools, consider the material you'll be working with and the volume of work expected. For heavy-duty projects, carbide bits are a worthy investment, whereas lighter tasks may not necessitate such premium tools.

Additionally, carbide bits provide better performance in terms of cutting speed and chip removal, which can enhance overall productivity. They also tend to maintain their sharpness longer, leading to more consistent and smooth finishes. However, if budget constraints are a concern, cobalt bits are a reasonable alternative, offering a balance between cost-effectiveness and performance.

Tips: Regular maintenance of your cutting tools can significantly extend their lifespan. Always ensure bits are clean and properly stored to avoid damage and edge wear.