FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

The Circular Saw Blade is an essential tool in both professional and DIY woodworking, playing a crucial role in ensuring precision and safety during cutting tasks. According to a report by the Woodworking Technology Institute, more than 70% of woodworking professionals rely on circular saws for their projects due to their efficiency and accuracy. However, improper use or selection of circular saw blades can lead to suboptimal results and increased safety risks.

Studies indicate that nearly 30% of accidents in the woodworking industry stem from the misuse of cutting tools, underscoring the importance of mastering the proper techniques for circular saw blade selection and handling. By understanding the nuances of different blade types and their specific applications, users can enhance their cutting precision while minimizing hazards.

This guide aims to provide essential tips and best practices for effectively utilizing circular saw blades, ensuring both quality workmanship and safety in every cutting endeavor.

Circular saw blades come in various types, each designed for specific cutting tasks. The standard carbide-tipped blade is versatile and suitable for general-purpose cutting in wood and engineered materials. For finer cuts, a blade with a higher tooth count is preferred, as it produces smoother edges and reduces chipping, making it ideal for plywood and paneling. On the other hand, a low-tooth count blade excels in cutting thick lumber quickly but may sacrifice finish quality.

Specialized blades also cater to specific materials. For instance, diamond blades are perfect for cutting concrete and masonry, while metal-cutting blades are engineered with coatings to reduce friction and heat during the cutting process. Understanding the right blade for the job not only enhances the quality of your work but also ensures safety by minimizing the risk of kickback and binding. By selecting the appropriate circular saw blade, you can achieve precision cuts while adhering to safety protocols, leading to more efficient and successful projects.

When it comes to mastering the use of circular saw blades, understanding essential features for precision cutting is crucial. The right blade can significantly impact the quality of your cuts. Look for blades designed specifically for the material you are working with, whether it's wood, metal, or composites. Factors like tooth count, blade diameter, and material quality directly influence cutting performance. A blade with more teeth generally offers smoother cuts, but may require more power to operate effectively.

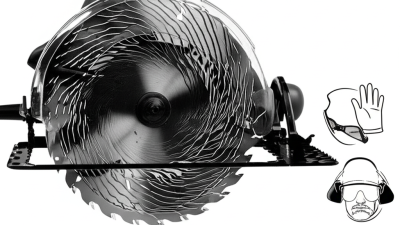

In addition to selecting the right blade, safety must be a priority when using circular saws. Always wear appropriate personal protective equipment, like safety goggles and gloves. It’s also essential to check the blade for damage before each use. A well-maintained blade not only extends its life but also ensures that you achieve precise cuts safely. Regularly clean the blade to prevent buildup that can affect performance.

With these tips, you can enhance your cutting accuracy and ensure a safe working environment, allowing you to focus on your projects with confidence.

When using circular saw blades, safety should always be a primary concern. According to the U.S. Consumer Product Safety Commission, about 37,000 emergency room visits each year are due to injuries from power saws, including circular saws. To minimize risks, users must ensure they are equipped with PPE (personal protective equipment) such as safety glasses, hearing protection, and durable gloves. One of the fundamental safety practices involves keeping the work area clean and well-lit to prevent slips and accidents.

Furthermore, maintaining proper blade alignment and ensuring the saw's guard is functional are crucial steps in enhancing safety. According to a report by the National Institute for Occupational Safety and Health (NIOSH), nearly 70% of saw-related injuries can be attributed to a lack of proper maintenance and operator training. Regularly inspecting blades for wear and ensuring they are fitted correctly can significantly reduce the likelihood of kickback—a common cause of injury. Always use the right blade for the material being cut and secure your workpiece to prevent movement. By implementing these best practices, users can significantly increase their safety while mastering the art of precise cutting with circular saws.

Achieving precise cuts with circular saws requires a deep understanding of both technique and the tools at hand. According to a report by the Power Tool Institute, nearly 70% of woodworking injuries are attributed to improper use of saws, highlighting the need for correct cutting procedures. One critical technique for precision cutting is using a straightedge or track system. This method ensures the saw moves in a straight line, significantly enhancing accuracy while minimizing the risk of blade drifting. Furthermore, maintaining a consistent feed rate while cutting is crucial; rapid movements can lead to uneven edges and increase the likelihood of kickback.

In addition to employing proper cutting techniques, selecting the right circular saw blade for your specific material is vital. A survey conducted by the Woodwork Career Alliance revealed that 65% of users achieve better results with blades specifically designed for the material they're cutting. For example, using a fine-tooth blade for plywood allows for cleaner cuts with less splintering, while a carbide-tipped blade is better suited for hardwoods. Keeping blades sharp and free from debris is also essential, as dull blades can create excess friction, leading to inaccuracies and potential safety hazards. By mastering these techniques, woodworkers can enhance their cutting precision significantly and ensure a safer working environment.

To ensure the longevity and performance of your circular saw blades, regular maintenance is essential. One of the key practices is keeping the blades clean. After each use, remove any resin or debris that may have accumulated during cutting. A simple solution of warm water and soap, alongside a soft brush, can effectively clean the blade. For tougher build-ups, a specialized blade cleaner can be beneficial. Regular cleaning prevents material from affecting the blade's sharpness and ensures precise cuts.

Another important aspect of maintenance is proper storage. Store your blades in a dry environment, preferably in a protective case or blade guard, to avoid exposure to moisture that could lead to rust. Additionally, avoid stacking the blades on top of one another, as this can cause warping or dulling of the edges. Lastly, always check the tension and alignment of the blade before use to ensure optimal performance. Keeping your circular saw blades in top condition will not only enhance their cutting efficiency but also extend their overall lifespan, allowing for safer and more precise work in the long term.

| Blade Type | Material Compatibility | Tooth Count | Cutting Thickness (inches) | Maintenance Tips |

|---|---|---|---|---|

| Carbide-Tipped | Wood, Laminate | 24-80 | 1/8 - 2 | Keep blades clean, store properly |

| Diamond Blade | Concrete, Masonry | 10-20 | 1/4 - 4 | Avoid overheating, use water cooling |

| High-Speed Steel (HSS) | Metal, Plastic | 20-36 | 1/8 - 1 | Sharpen regularly, lubricate |

| Aluminum Cutting Blade | Aluminum, Non-ferrous Metals | 40-80 | 1/8 - 1 | Avoid gummy buildup, use with care |