FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

In the world of construction and masonry, selecting the right tools is crucial. Among these tools, the Brick Grinding Disc stands out for its versatility. A report by Research and Markets indicates that the global power tools market is projected to reach $50 billion by 2026. This growth highlights the increasing demand for efficient tools like grinding discs.

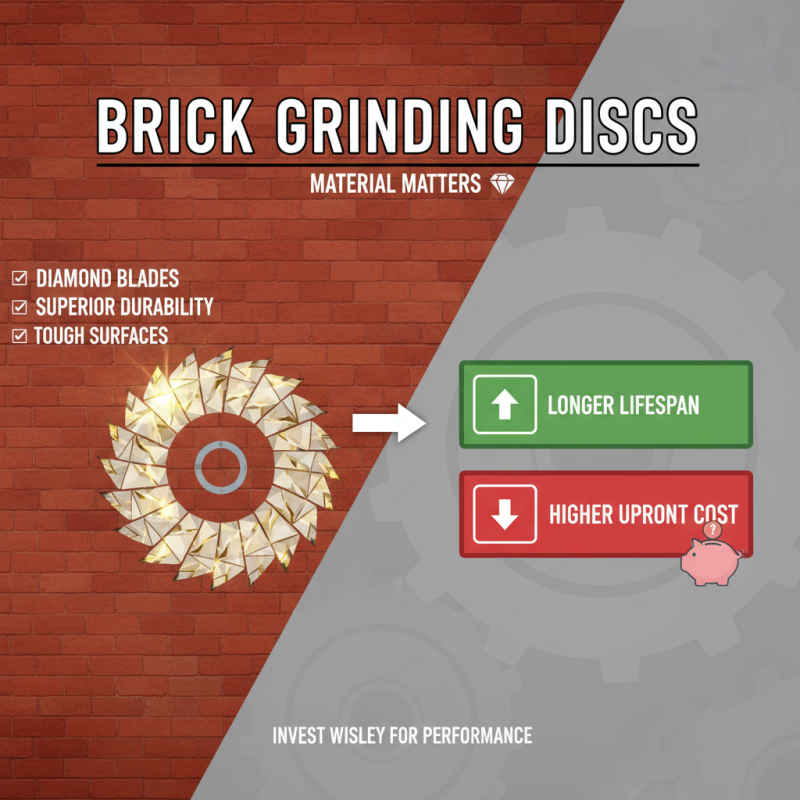

Brick Grinding Discs vary in material and style, catering to specific tasks. For instance, diamond blades are popular due to their durability. However, choosing the wrong disc can lead to poor performance and safety issues. The right choice can increase productivity by up to 30%, according to industry insights. Still, many users often overlook the importance of quality and compatibility.

Despite advancements, challenges remain. Many consumers are unaware of how material affects lifespan. This misunderstanding can lead to costly mistakes. Diligence in selecting the best Brick Grinding Disc can mean the difference between a successful project and a frustrating experience. Exploring the options available in 2026 and understanding what to consider will empower users to make informed decisions.

When choosing a brick grinding disc, the material significantly impacts performance. Diamond blades are popular for their durability. They easily handle tough surfaces. Their lifespan is longer than other materials. However, they can be more expensive upfront. Users might hesitate to invest initially.

Ceramic discs are another option. They offer good precision and smooth finishes. Many prefer them for around-the-house projects. Their lightweight nature makes them easy to use. On the downside, they may wear out quickly on harder materials. This raises questions about cost-effectiveness over time.

Metal-bonded discs are solid choices for heavy-duty tasks. They provide excellent strength and longevity. Yet, they may not deliver the finest finish. Users should assess their needs carefully. Each material has pros and cons, leading to potential pitfalls in decision-making. Consider the project type and frequency of use before purchasing.

When it comes to grinding discs for bricks, understanding specifications is crucial. Grit size plays a significant role in how effectively a disc can cut through materials. A lower grit number signifies a coarser disc, suitable for faster removal of material. These discs wear down quickly but are effective in shaping bricks. Higher grit sizes provide a smoother finish, ideal for fine-tuning edges. Combining different grit sizes may yield better overall results.

Bond types also matter significantly. They determine how the abrasive material is held together. There are resin, metal, and ceramic bonds. Resin provides flexibility and is well-suited for varied applications. Metal bonds offer durability and are ideal for heavy-duty tasks. Ceramic bonds provide excellent sharpness and longevity, yet they can be more rigid. Choosing the right bond type affects performance during grinding.

It's essential to reflect on the compatibility between the disc and the grinding machine. Not all combinations work well together. A mismatch can lead to poor results or damage. Testing out various combinations may seem tedious, but it can dramatically enhance efficiency. Understanding these specifications allows for better choices and more effective outcomes in brick grinding.

When choosing the best brick grinding discs, understanding the landscape of brands is essential. Each brand offers distinct features and performance levels. Some focus on durability, while others prioritize cutting speed. It's crucial to evaluate these characteristics based on your specific needs.

Comparing various brands can be enlightening. Certain options may excel in certain tasks, but not all are versatile. Users often report mixed experiences with different products. It is vital to consider feedback from fellow professionals. Durability and efficiency can vary significantly across brands.

Moreover, market trends change frequently. Innovations emerge, and older models may fall behind. Users need to stay informed about new arrivals. Evaluating performance, longevity, and cost can lead to surprising insights. An in-depth analysis ensures you find the right match for your brick grinding needs. It’s a process that takes time and careful consideration.

When using grinding discs, safety is paramount. Reports indicate that improper use can lead to severe injuries, including eye damage and lacerations. A study published by the American National Standards Institute highlights that around 4,000 injuries occur annually due to grinding operations. This underscores the need for adherence to safety standards.

Protective gear is essential. Always wear safety goggles, gloves, and a face shield. These items reduce the risk of injury significantly. Regular training on proper usage is also critical. Workers should be familiar with the varying types of grinding discs and their specific applications. Not every disc is suitable for every material, like brick or concrete. Familiarity with these details can avert dangerous mistakes.

Proper maintenance of grinding equipment cannot be overlooked. Discs should be inspected for damage before each use. Cracks or chips are red flags. Operators often overlook these small details, which can lead to catastrophic failures. Moreover, the workspace should be clean and organized to minimize risks. A cluttered area can contribute to accidents. Ensuring a safe environment is just as important as using the right tools.

| Disc Type | Material | Diameter (mm) | Max RPM | Safety Standard | Best Practices |

|---|---|---|---|---|---|

| Diamond Grinding Disc | Diamond | 125 | 12,200 | EN 13236 | Use appropriate PPE; Check for cracks before use |

| Alumina Oxide Disc | Alumina | 115 | 13,300 | OSHA 29 CFR 1910 | Follow RPM ratings; Immediately replace any damaged discs |

| Silicon Carbide Disc | Silicon Carbide | 150 | 10,000 | ISO 9001 | Ensure correct attachment to machine; Keep workspace clean |

| Resin Bond Disc | Resin | 125 | 11,500 | ANSI B7.1 | Use moisturized cutting whenever possible; Check attachment frequently |

In 2026, brick grinding discs are evolving rapidly. New technologies are emerging that enhance performance and durability. One key innovation lies in advanced composite materials. These materials improve the efficiency of grinding while reducing wear and tear. They promise to offer cleaner cuts and longer service life.

The integration of smart technologies is a fascinating trend. Some discs may include sensors that monitor grinding performance. This data helps users adjust techniques in real-time. Instant feedback can lead to improved precision and reduced waste. However, such technology requires learning curves and adjustments from traditional methods.

Tips: Always check compatibility before purchasing. The right size is crucial. Ensure you’re using the correct disc for your specific projects. A wrong fit can lead to frustrating results. Also, remember to consider the environment. Use discs with less dust generation to create safer workspaces. Adapting to new tools can be difficult, but the benefits are often worth the effort.