FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

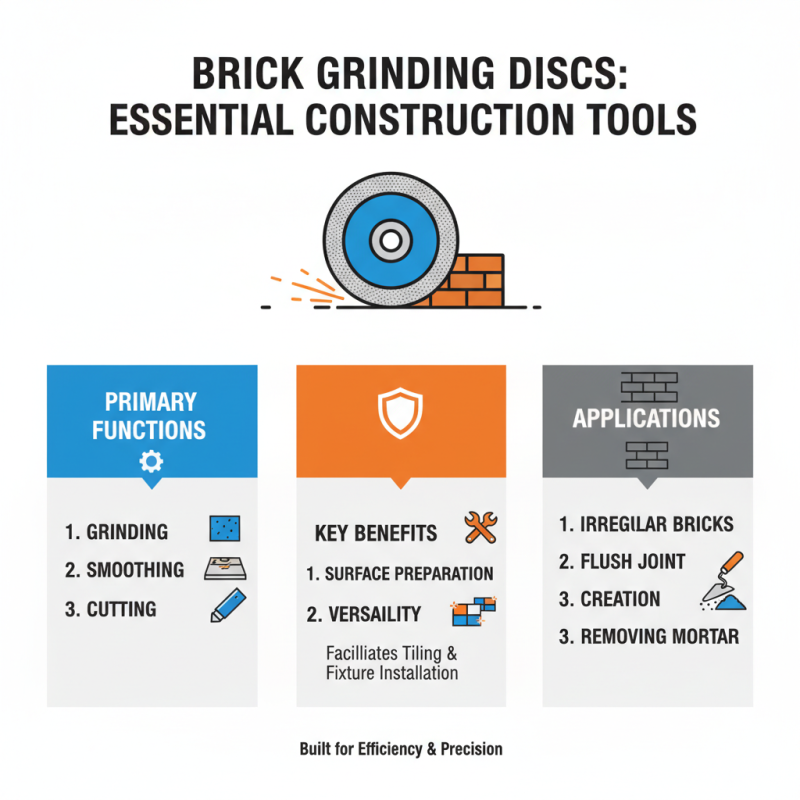

In the realm of construction and masonry, the importance of a Brick Grinding Disc cannot be overstated. According to the "Construction Tools Market Report 2023," tool efficiency can increase productivity by over 30%. A Brick Grinding Disc is specifically designed to enhance the finishing of brick surfaces, ensuring a clean and polished result. As industry expert Sarah Mitchell states, "A quality grinding disc can make all the difference in achieving precision and durability in brickwork."

The versatility of a Brick Grinding Disc is evident in various applications. It can be used for both grinding and sharpening, making it essential for masonry professionals. It’s essential to select the right disc for the job, as different materials require different specifications. Unfortunately, many users often ignore this crucial detail, leading to subpar results.

Inadequate understanding of the Brick Grinding Disc could be a costly oversight. Many professionals underestimate the significance of choosing the appropriate grit and bonding material. Such mistakes can result in inefficiency and increased workload. By acknowledging these common pitfalls, users can enhance their outcomes and fully harness the potential of Brick Grinding Discs in their projects.

Brick grinding discs are essential tools used for shaping and finishing brick surfaces. They consist of a metal body with an abrasive coating, usually made from diamond particles or aluminum oxide. This design allows the disc to efficiently grind down rough edges and remove imperfections from brick materials. The composition ensures durability, even under rigorous use.

When using a brick grinding disc, ensure you wear proper safety gear. Dust and debris can be hazardous. A mask and goggles will help protect you. Holding the grinder firmly will prevent slips. This is crucial for achieving a clean and precise finish.

Tips: Start with a light touch. Pressing too hard can damage the disc or the material. It's better to gradually increase pressure as needed. Also, check the disc for wear and tear before each use. A worn disc may not perform effectively, leading to unsatisfactory results. Practice on scrap materials if you're inexperienced. This helps build confidence and skill.

Brick grinding discs are essential tools in construction and renovation. These discs are designed to grind, smooth, and cut through brick surfaces effectively. This makes them invaluable for various applications. For instance, they can help create a flat surface on irregular bricks. This is crucial for tasks like tiling or installing fixtures.

In renovations, brick grinding discs excel in removing old mortar or paints. This process prepares the surface for new applications. However, using these tools requires caution. Over-grinding can damage the underlying structure, leading to costly repairs. Also, the dust produced can be harmful if not managed properly. Always wear proper safety gear.

Construction sites often demand precision. A brick grinding disc can make the job faster, but it can also produce uneven surfaces if misused. Regular practice and attention to detail are vital. Understanding the tool’s capabilities can prevent mistakes. Embracing these imperfections helps improve future projects.

When using a brick grinding disc, safety is vital. Follow this step-by-step guide to ensure a smooth process. Start by wearing appropriate safety gear. This includes goggles, gloves, and a dust mask. These protect against flying debris and fine particles.

Next, secure the brick firmly. Use a clamp or vise to keep it steady. A wobbly brick can lead to unpredictable results. Make sure your workspace is clear. A tidy area reduces the risk of accidents.

When you begin grinding, use steady, light pressure. Too much pressure can cause the disc to wear unevenly. Industry reports suggest that over 40% of users apply excessive pressure during use, leading to premature disc failure.

Tips: Regularly check the disc for wear. Replace it if you notice cracks or uneven surfaces. This prevents accidents. If you're a beginner, practice on scrap pieces before tackling your main project. This builds confidence.

Lastly, remember to keep your hands clear of the grinding path. Safety should always come first. Reflect on your technique after each use. Learning and improving is part of the process.

Maintaining your brick grinding disc is essential for its longevity and performance. Regular cleaning can enhance its effectiveness. After each use, take a moment to remove debris. A simple brush can do wonders. It ensures the disc stays sharp and ready for the next job. Sometimes, it's easy to overlook this step, but neglecting it can lead to reduced efficiency.

Another key aspect is proper storage. Keep your grinding disc in a dry, cool place. Avoid humid environments that can cause rust. Ensuring it is well protected also prevents accidental damage. A solid container can shield it from impacts. Some may forget about this aspect, leading to unnecessary wear and tear.

Inspect your disc frequently for any signs of damage. Look for cracks or wear that could impact performance. Using a damaged disc can lead to unsafe working conditions. If you identify any issues, replace it promptly. Remember, taking small steps in maintenance can save you time and costs in the long run. Set reminders if needed, so it's never neglected.

When analyzing brick grinding discs, three crucial aspects stand out: material composition, performance metrics, and application suitability. Common materials include diamond, silicon carbide, and aluminum oxide. Each material offers distinct advantages. For example, diamond discs are known for their superior longevity and efficiency. They can last up to three times longer than silicon carbide, yet they are often more expensive.

Performance metrics often hinge on grit size and bond type. Coarser grits remove material quickly but leave a rough finish. Finer grits provide a smoother result, suitable for finishing work. Reports indicate that utilizing the correct grit can improve efficiency by as much as 30%. In practical terms, achieving the right balance is challenging. Many users struggle to select the ideal disc for specific tasks.

Environmental factors also influence performance. High temperatures can affect the integrity of the disc, leading to premature wear. Users should regularly inspect their discs for signs of wear or damage. Data show that neglected tools can reduce effectiveness by over 40%. Understanding these variables is crucial for optimal use. The right brick grinding disc can make all the difference for efficiency and finish quality.