FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

Choosing the right 16mm drill bit for your project is crucial. The wrong bit can lead to poor results and wasted time. A high-quality 16mm drill bit can make the difference between a successful task and a frustrating one.

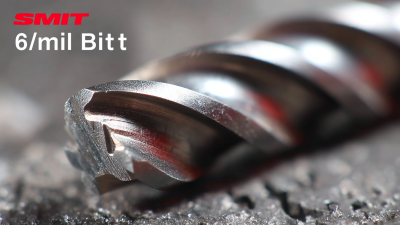

When selecting a 16mm drill bit, consider the material you will be drilling. Different materials require different types of bits. For example, wood, metal, and concrete each need specific features in a drill bit. It is essential to match your bit to the project at hand.

Pay attention to details like the drill bit's design and construction quality. A well-made 16mm drill bit can last longer and perform better. However, not all bits are created equal. Some may wear out quickly or struggle with certain materials. Reflect on your options, and don’t rush the decision-making process. Taking time to choose wisely can prevent headaches later.

When choosing a 16mm drill bit, it's essential to understand the different types available. Each type serves various purposes. For instance, twist bits are commonly used for general drilling. They are versatile and can work with wood, metal, and plastic. The spiral design helps in cutting effectively, which is why many prefer them. But sometimes, they may not provide the precision needed for certain projects.

Spade bits, on the other hand, are another option. These are great for drilling large holes quickly in softer materials like wood. Their flat design allows for a broader cut. However, they can leave rough edges, requiring additional work to smooth the surface later.

Chisel bits are also worth considering. They work well for creating holes in tougher surfaces but can be tricky to use. Beginners may struggle with maintaining control, leading to uneven holes.

Finding the right 16mm drill bit involves assessing the materials you plan to use. Each bit type has its strengths and weaknesses. A bit might excel in one area but fail in another. It's crucial to reflect on your project's requirements and choose accordingly. Test different bits, if possible. Understanding their unique traits can significantly affect your project's outcome. This trial and error approach may seem daunting, but it helps in honing your skills.

When selecting a 16mm drill bit, understanding the specific project is essential. Consider the material you will be drilling into. Wood, metal, and plastic require different drill bit designs. For example, a wood drill bit has a pointed tip, allowing easier penetration. In contrast, metal drill bits are usually made from high-speed steel for durability.

Another factor is the drill bit's length. Shorter bits provide greater stability, ideal for dense materials. Longer bits can reach deeper spots but may wobble. Additionally, check the shank size. It should fit your drill tightly to avoid slippage during use.

Tips: Always wear safety goggles. This protects your eyes from debris. Drill at a slow speed to prevent overheating. Doing so prolongs the bit's life.

Lastly, don’t overlook the coating. Coated drill bits resist corrosion and reduce friction, improving efficiency. Pay attention to your choice; it can affect the outcome of your project. Often, even experienced DIYers choose the wrong bit, leading to mistakes. Reflecting on your past projects helps inform your next choice.

Choosing the right 16mm drill bit depends heavily on the material you'll be working with. Different materials require different drill bit types to ensure effectiveness. For example, wood requires a sharp, pointed bit for clean holes, while metal requires bits made from high-speed steel. Each material has its unique challenges. If you use the wrong bit, you may end up with damaged surfaces and forgotten holes.

Consider the density of your material. Softer materials, like softwood, can be drilled easily with a standard bit. However, harder materials like stainless steel may need a specialized bit. Pay attention to the drill bit's coating as well. Some coatings enhance performance, while others can create friction when not used correctly.

Mistakes can happen. Maybe you start with the wrong bit, or perhaps you rush the drilling process. These errors can cause frustration and waste time. Reflecting on your material compatibility is key. Adjust your approach based on your project's requirements. Always double-check what you need before drilling begins.

| Material Type | Recommended Bit Type | Speed Setting (RPM) | Lubrication Requirement |

|---|---|---|---|

| Wood | Twist Bit | 3000-4000 | None |

| Aluminum | Cobalt Bit | 2000-3000 | Yes (Oil) |

| Steel | M42 Bit | 1500-2500 | Yes (Cutting Fluid) |

| Masonry | Carbide Bit | 500-1000 | None |

| Plastic | Spiral Bit | 2000-3000 | None |

Choosing the right 16mm drill bit can significantly affect the success of your project. Understanding specific applications is crucial. For instance, wood requires a different kind of drill bit compared to metal. Wood bits often have a pointed tip, while metal bits usually feature a more robust design.

When working on masonry, a carbide-tipped drill bit may be necessary. According to industry data, using the incorrect bit can lead to poor performance and increased wear. Reports show that nearly 30% of projects fail because of improper tool selection. This highlights the importance of using the right drill bit.

Consider your material carefully. For precision tasks, such as creating pilot holes, a high-speed steel (HSS) bit is ideal. However, for tougher materials, a more resilient option is sometimes needed. It's also worth noting that not every drill bit guarantees efficiency. Reflect on previous projects where mistakes were made. Such reflections can help inform better choices in future tasks. Choosing the right drill bit is indeed a nuanced process.

Maintaining your 16mm drill bit is crucial for optimal performance. Regular care prevents premature wear. According to a recent industry report, improper maintenance can reduce a drill bit's life by up to 50%. Keep the bit clean and free from debris. After each use, wipe it down with a soft cloth. This simple step keeps your tool sharp and efficient.

Sharpening your bit is essential. A dull drill bit can overheat and become damaged. Research indicates that a sharp bit completes projects faster, improving efficiency by 30%. Invest in a quality sharpening tool. Follow instructions carefully. Misuse can lead to further damage. Check regularly for any signs of wear. A proactive approach is always better than reactive fixes.

Store your drill bit properly. Avoid damp environments that cause rust. Use a dedicated case or container. This not only protects the bit but also promotes longevity. Remember, even minor imperfections can impact performance. Regularly assess your tools. Reflect on their maintenance routines to ensure they meet your project needs.