FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

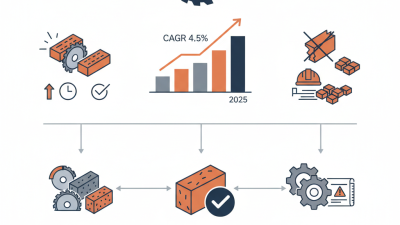

Choosing the right Brick Cutting Blade is essential for any masonry project. According to industry expert Mark Taylor, "A suitable brick cutting blade can make all the difference in performance." This statement captures the essence of the decision-making process.

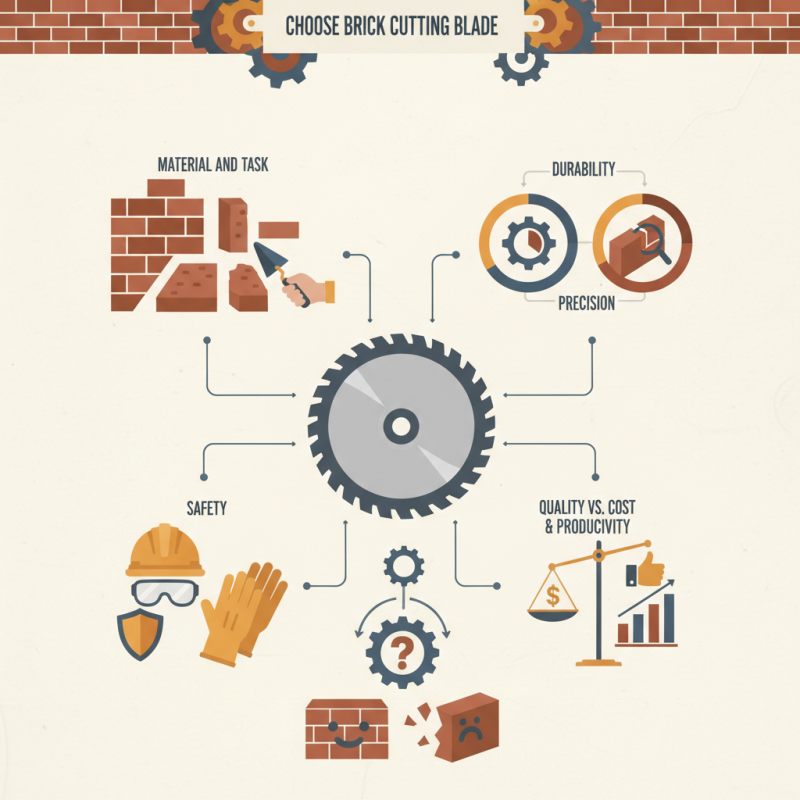

Selecting a blade involves understanding the material and task at hand. Different blades offer varied features, such as diamond-cutting edges or segmented designs. These features affect durability and precision. A wrong choice can lead to inefficient cutting, resulting in wasted time and resources.

It's also important to consider the safety aspects. Using an incorrect Brick Cutting Blade can endanger the user. Always prioritize quality over cost. Reflect on your needs and project scope. The right blade can enhance productivity, while the wrong one could cause frustration.

When it comes to brick cutting blades, there are various types to consider. Diamond blades are popular for their durability and cutting efficiency. They provide clean cuts and last longer than other options. However, they can be more expensive.

Wet cutting blades are another option, designed to reduce dust and heat during cutting. They work well for larger projects. Yet, they often require a water source, which might not be readily available. An additional concern is choosing the right size for your cutting machine. A poorly fitted blade can lead to uneven cuts.

A wall cutter blade is specialized for thicker materials, making it suitable for construction workshop needs. But these blades can be heavier and harder to control. Weighing cost versus functionality is crucial. Each type of blade has its pros and cons that need reflection before making a decision.

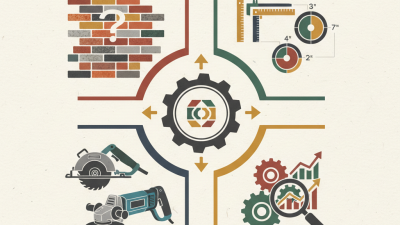

Choosing the right brick cutting blade is crucial for any masonry project. There are several factors to consider before making a decision. The type of material in the bricks is an essential aspect. Different bricks require different blades. For instance, softer bricks need different cutting teeth compared to harder varieties.

Another important factor is the blade diameter. Larger blades can handle thicker bricks but may be harder to control. A smaller blade provides precision but may struggle with thicker materials. It’s essential to assess the thickness of the bricks you will work with to select an appropriate size.

**Tips:** Look for blades with cooling holes. They help prevent overheating during long cutting sessions. Additionally, consider the RPMs recommended for your blade type. Clean cuts and longer-lasting blades are often the result of the correct RPM. Finally, remember that price does not always equate to quality. Sometimes, a mid-range option may surprise you with its durability. Experimentation can lead to unexpected findings.

Choosing the right brick cutting blade is crucial for your project. The blade material matters greatly. Common options include diamond and carbide. Both have their strengths and weaknesses.

Diamond blades are known for their durability. They cut through hard materials efficiently. However, they can be expensive and wear out over time. On the other hand, carbide blades are often cheaper. They also perform well with softer materials but may not last as long on tougher jobs.

Consider your cutting needs carefully. What type of brick are you using? How thick is it? If you’re unsure, asking for advice can help. Don’t rush the decision. Testing a few options can lead to better results. Taking the time to reflect on your choices may save you time and money later.

| Blade Material | Best For | Advantages | Disadvantages |

|---|---|---|---|

| Diamond | Cutting hard bricks, concrete | Long-lasting, efficient cutting, heat-resistant | More expensive than other options |

| Carbide | General brick cutting | Durable, cost-effective | Wears out faster than diamond |

| High-Speed Steel (HSS) | Soft bricks and masonry | Affordable, good for less dense materials | Not suitable for hard materials |

| Steel | Light cutting tasks | Easy to find, inexpensive | Limited lifespan, not for heavy-duty work |

Choosing the right blade for cutting bricks requires careful consideration of diameter and thickness. The diameter can influence the cutting depth and the speed of the cut. A larger diameter usually allows for deeper cuts. This is beneficial when working with thick bricks. However, larger blades can be heavier. If you're not prepared for the extra weight, handling may become cumbersome.

The thickness of the blade also plays a crucial role. Thicker blades tend to be more durable and can withstand heavy use. But they may also lead to wider cuts, which can waste material. On the other hand, thinner blades offer precision. Yet they wear out faster and can break under excessive pressure. Finding the right balance between size and durability is essential.

It’s essential to match the blade to your specific project needs. A trial-and-error approach may be necessary to determine what works best. Remember, even experienced users sometimes make mistakes in blade selection. Reflecting on these choices can help improve future projects. Consider your cutting frequency and the types of bricks you will use. This way, you can select a blade that truly meets your needs.

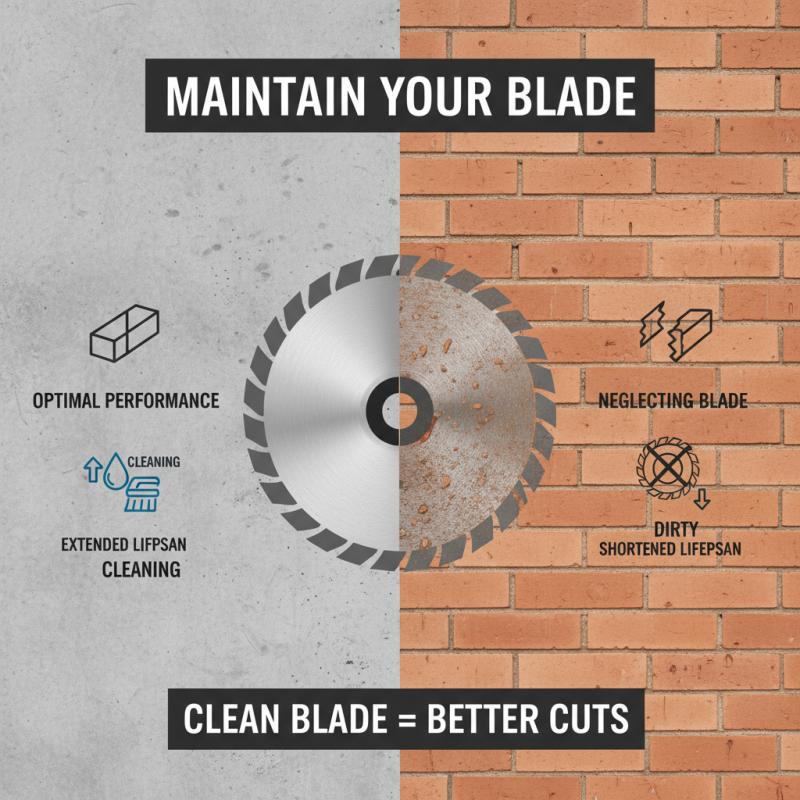

Maintaining your brick cutting blade is essential for optimal performance. Regular cleaning helps remove dust and debris that can accumulate after cutting. You might find it easy to neglect this step, but it is crucial. A dirty blade cannot cut effectively, leading to uneven results and a shortened lifespan.

When using the blade, monitor the resistance during cutting. If the blade seems to struggle, it may be time for a replacement. Avoid excessive pressure; a gentle, steady approach is often more effective. Over time, you might notice the blade wearing out. This is a sign to review your cutting technique. Poor cutting can lead to faster degradation of the blade.

Store your blades in a dry, protected space. Moisture can lead to rust and corrosion. Also, check the blade for any chips or cracks before each use. Small issues can escalate quickly if overlooked. Keep a record of how long you've used each blade. Sometimes, we forget to replace them until it’s too late. Regular checks can save you from unexpected failures during projects.