FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

Choosing the right Brick Cutting Blade is crucial for successful masonry work. According to John Smith, a veteran in the brick-cutting industry, “A high-quality blade can make all the difference.” His experience highlights the importance of selecting the proper equipment.

When it comes to cutting bricks, the right blade impacts both precision and durability. A good Brick Cutting Blade can prevent chipping and ensure clean cuts, but not all blades are created equal. You might find yourself overwhelmed by the choices available on the market. Some professionals frequently overlook the subtle differences in blade composition and grain. This can lead to frustration, especially during critical projects.

It's essential to reflect on your specific needs. Are you cutting dense bricks or softer materials? Each requires a tailored approach. Investing in a quality Brick Cutting Blade is worth considering. It can save time and reduce long-term costs. Still, many users make the mistake of prioritizing price over performance. This is an area that invites reconsideration.

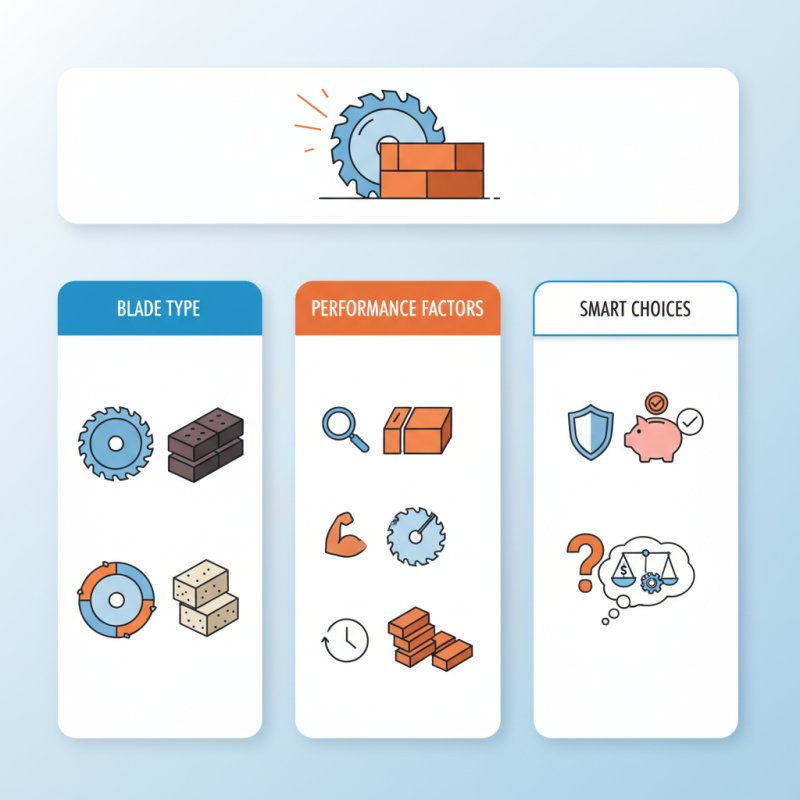

When selecting the right brick cutting blade, understanding the different types available is essential. There are various categories of blades that cater to specific cutting needs. For instance, diamond blades are popular for their durability and efficiency. They can cut through tough materials with minimal effort. Research shows that using diamond blades can increase cutting speed by 30%. This is crucial for projects with tight deadlines.

Other options are segmented blades, which are excellent for dry cutting. They allow for better cooling and less dust. These blades can be less expensive, yet they may not last as long. A 2020 industry report indicated that segmented blades wear out 20% faster compared to continuous rim blades. Knowing the lifespan can influence your choice. Moreover, each blade type has its safety considerations. Operators must wear appropriate gear to prevent injuries.

Often, users overlook the importance of matching the blade type with the material. For example, a blade efficient on concrete may not be effective on soft bricks. This can lead to frustration and even project delays. A mismatch can reduce performance by up to 25%. Thus, knowing the material type is as important as the blade type.

When selecting a brick cutting blade, several key factors play a crucial role. Understanding the material of the bricks is vital. Different bricks, such as clay or concrete, require specific blades. For instance, blades designed for concrete typically feature diamond abrasives. According to industry reports, choosing the right material can increase blade efficiency by up to 50%.

Another essential aspect is the diameter of the blade. Larger blades tend to cut faster but may be less maneuverable. A study showed that a 10-inch blade might reduce cutting time by 30% compared to smaller blades. However, it is essential to match the size with your cutting tool. Using the wrong size could lead to dangerous kickbacks.

Tip: Always check the teeth configuration on the blade. A finer tooth may be better for intricate cuts. However, a thicker tooth can handle more rigorous work. It's essential to balance precision with the job's demands. Remember to evaluate both cost and quality. A higher price doesn’t always guarantee better performance. Reflections on past purchases can guide this choice effectively.

| Factor | Description | Recommended Blade Type |

|---|---|---|

| Material | Consider the type of brick you are cutting (e.g., firebricks, concrete, etc). | Diamond Blade |

| Blade Diameter | Select a diameter that fits your saw and suits the cutting depth needed. | 12" - 14" Blades |

| Cutting Speed | Choose a blade that allows for efficient cutting speed while maintaining precision. | Turbo Blades |

| Wet vs. Dry Cutting | Determine if you need a wet cutting blade for reduced dust and cooling or a dry cutting blade for convenience. | Wet Blade |

| Blade Thickness | Thicker blades may last longer, while thinner blades can provide cleaner cuts. | 1/8" to 1/4" Thickness |

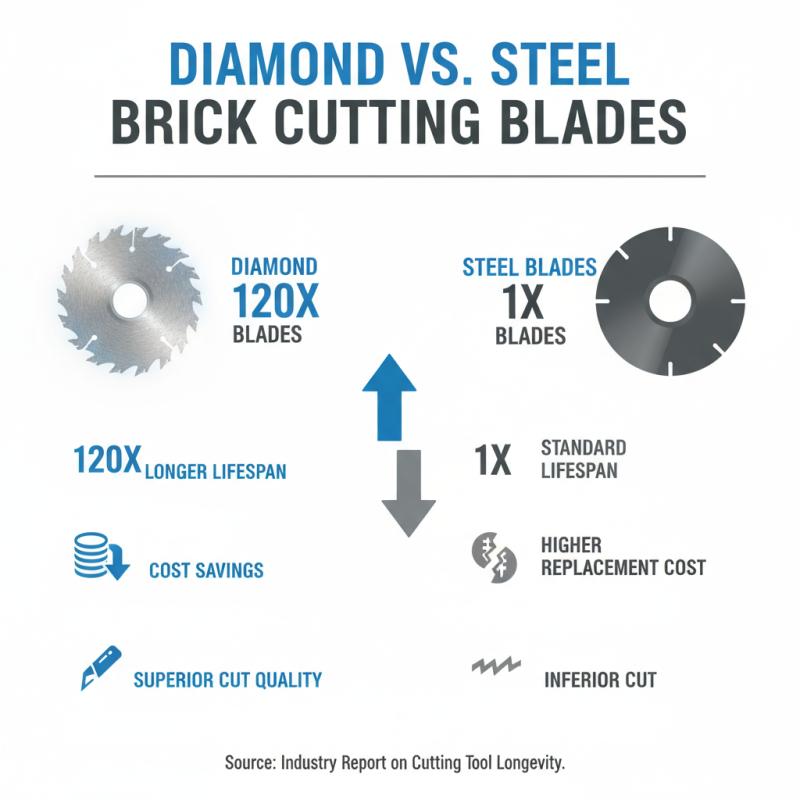

When it comes to cutting bricks, choosing the right blade material can greatly affect efficiency and quality. Diamond blades are often favored due to their sharpness and durability. A recent industry report reveals that diamond blades can last up to 120 times longer than standard steel blades. This longevity can result in significant cost savings over time.

However, not all tasks require a diamond blade. For softer bricks or occasional use, other blade materials might suffice. These alternatives may be less expensive but can wear out quickly. Users often find themselves replacing these blades frequently, which can increase overall costs. Assessing the type of brick and the volume of work is crucial in making the right choice.

**Tips:** Consider the specific job. For heavy-duty tasks, invest in diamond blades. For light work, less durable materials might be acceptable. Always review maintenance needs. A poorly maintained blade can underperform regardless of the material. Balance your budget with job requirements to optimize your tools.

Choosing the right brick cutting blade is crucial for achieving the best results. One of the key factors to consider is blade size. The wrong size can lead to inefficient cutting. A smaller blade might struggle with thick bricks, while a larger one could be cumbersome and difficult to control. Finding the perfect balance is essential for smooth operations.

Compatibility with tools is equally important. Not all blades fit every cutting tool. Some may require adapters, which could complicate your project. If a blade doesn’t sit properly, it can cause vibration and uneven cuts. Always check your tool specifications before purchasing a blade.

Here are some tips: Measure your tool's arbor size. This will help you choose a compatible blade. Pay attention to the blade's RPM rating as well. Mismatched speeds can lead to accidents. Lastly, always test the blade on scrap material. This allows you to assess performance without wasting actual bricks.

Reflecting on these factors can help avoid unpleasant surprises during your project. It’s worth taking the time to choose wisely.

When using brick cutting blades, safety is paramount. According to industry reports, nearly 30% of accidents result from improper blade handling. Always wear a proper safety helmet, goggles, and gloves to protect against debris. A dust mask is also advisable to avoid inhaling harmful particles. These simple measures can drastically reduce the risks involved.

Before starting, check your equipment. Make sure the blade is properly secured and in good condition. An unstable blade can lead to accidents and inaccuracies. The American National Standards Institute emphasizes the importance of maintaining machinery. Regular inspection ensures optimal performance, which directly correlates with safety. A badly worn or cracked blade should be replaced immediately.

During the cutting process, take your time. Rushing can lead to costly mistakes and injuries. Hold the cutting tool firmly, using both hands if possible. This gives you better control and reduces vibration. Watch your surroundings, too. The environment can pose hidden dangers. Maintaining a clean workspace reduces trip hazards. Ultimately, awareness and preparation enhance safety when using brick cutting blades.

This chart illustrates the important factors to consider when choosing the right brick cutting blade. Each criteria is represented by a percentage, indicating its relative importance in making an effective selection.