FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

In the ever-evolving world of construction and masonry, mastering the art of Brick Grinding has emerged as a crucial skill for professionals and enthusiasts alike. As we step into 2025, the need for efficient and effective grinding techniques has never been more pronounced. Whether for preparing surfaces, enhancing aesthetics, or ensuring structural integrity, understanding the nuances of Brick Grinding can significantly impact project outcomes.

This ultimate guide aims to equip readers with comprehensive knowledge of various Brick Grinding techniques, tools, and best practices tailored for the modern era. From selecting the right equipment to mastering techniques that optimize performance and minimize waste, we will delve into the essential aspects of this valuable skill. With advancements in technology and a growing focus on sustainability, the methods discussed in this guide will not only enhance the quality of work but also promote environmentally-friendly practices within the masonry industry.

Join us as we explore innovative approaches, safety tips, and expert insights into Brick Grinding, empowering you to elevate your craftsmanship and achieve outstanding results in all your masonry endeavors. Whether you are a seasoned professional or a newcomer to the field, this guide will serve as an invaluable resource in navigating the pivotal trends and techniques shaping Brick Grinding today.

Brick grinding is an essential technique in masonry and construction, aimed at refining the surface of bricks for better adhesion, aesthetics, and structural integrity. At its core, brick grinding involves the use of specialized tools and equipment to smooth rough edges, remove mortar residue, and prepare bricks for further application. Understanding the foundational principles of this technique is crucial for both novice and experienced workers in the field.

The basic process of brick grinding typically begins with assessing the condition of the bricks. Workers must identify any imperfections that need addressing, such as uneven surfaces or old mortar. Once this assessment is complete, the right grinding tools, such as angle grinders or diamond blades, are chosen based on the specific needs of the project. Safety precautions, including the use of protective gear, are imperative during the grinding process to prevent accidents and ensure a clean work environment. Proper technique and careful control are essential to achieve a consistent finish while preserving the integrity of the brick.

When it comes to effective brick grinding, having the right tools and equipment is crucial for achieving professional results. The first essential tool is a high-quality angle grinder, which allows for precise and efficient material removal. With the appropriate grinding disc, such as diamond or silicon carbide, users can easily tackle various brick surfaces, ensuring a smooth finish. Additionally, using a wet grinder can significantly reduce dust and improve the overall efficiency of the grinding process, making it an ideal choice for larger projects.

In addition to grinders, protective gear is vital for safe operation. Dust masks and safety goggles protect against harmful particles and debris flying during grinding. Other recommended tools include chisels and hammers for initial shaping and adjusting, as well as a vacuum system to keep the workspace clean. By combining these tools with proper techniques, brick grinding can become a manageable and effective task, leading to stunning results in both construction and renovation projects.

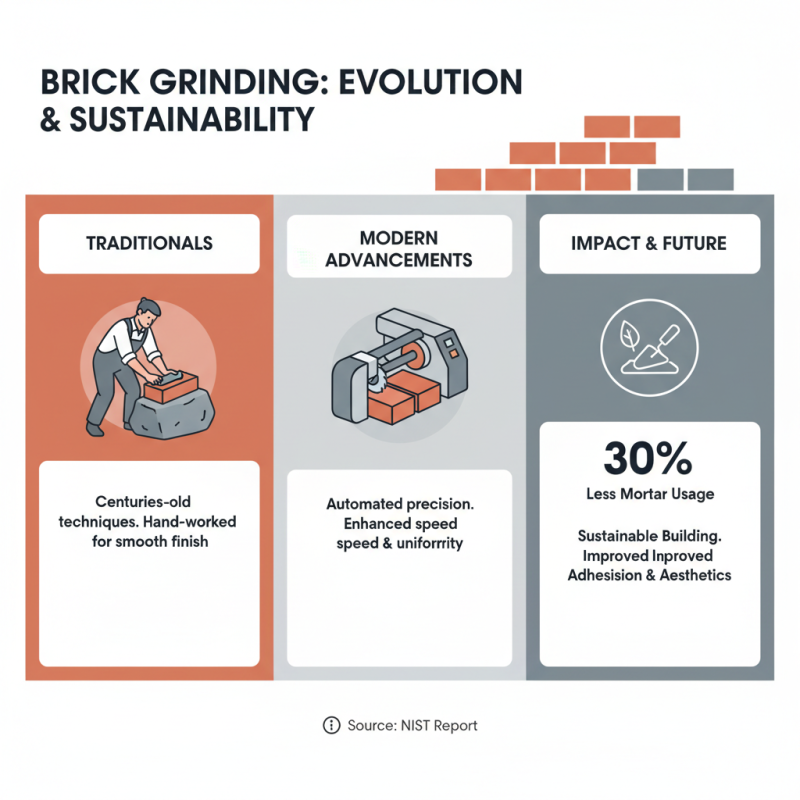

Brick grinding, a crucial technique in masonry and construction, has evolved over time, incorporating various traditional methods that craftsmen have used for centuries. The process primarily involves refining the surface of bricks to enhance their aesthetic appeal and ensure better adhesion during building projects. According to a report by the National Institute of Standards and Technology, properly ground bricks can reduce mortar usage by up to 30%, leading to more sustainable building practices.

Traditional brick grinding methods include hand grinding, where artisans utilize abrasive wheels or stones to manually refine the brick surfaces. This approach not only allows for precision in shaping but also fosters a connection to the material, ensuring that each brick is treated with care. In a survey conducted by the Masonry Contractors Association, 67% of masonry professionals still prefer traditional grinding methods for projects that require bespoke masonry work due to the unique textures and finishes achieved.

Moreover, the adoption of modern technology in traditional grinding methods, such as the use of diamond grinding wheels, has significantly improved efficiency without compromising the craftsmanship value. This hybrid approach has led to a 40% reduction in grinding time while maintaining the integrity of the brick's surface. As we move into 2025, understanding these traditional techniques remains vital for builders aiming for both aesthetic quality and structural integrity in their projects.

Modern innovations in brick grinding technology are transforming how masonry professionals approach their craft. The latest advancements include the integration of smart machinery equipped with AI-driven precision algorithms. These machines not only ensure that brick surfaces are ground to the exact specifications but also reduce the waste associated with over-grinding. Additionally, the development of advanced grinding wheels made from diamond compounds enhances durability and effectiveness, allowing for cleaner cuts and faster work rates.

When using modern grinding techniques, it’s crucial to prioritize safety and efficiency. One tip is to always use protective gear such as goggles and gloves to shield against dust and debris. Moreover, maintaining a consistent speed while grinding can prevent overheating and prolong the life of both the tool and the materials being worked on.

Another important aspect to consider is the use of dust extraction systems. These systems not only improve air quality and visibility on the job site but also help in complying with health regulations. Ensuring that your workspace is clean and organized can significantly enhance overall productivity, allowing for more effective time management during projects. Implementing these innovative techniques and tips can lead to improved outcomes and a more streamlined workflow in brick grinding.

This chart illustrates the efficiency of different brick grinding techniques projected for 2025. As seen, robotic grinding shows the highest efficiency, followed closely by laser grinding. Traditional methods still play a role but are significantly outperformed by modern innovations.

When engaging in brick grinding, ensuring safety is paramount. Protective gear such as safety goggles, dust masks, and gloves should be worn to safeguard from flying debris and harmful dust particles. The grinding process can generate significant dust, which might contain crystalline silica, a hazardous material if inhaled over prolonged exposure. Make sure to work in a well-ventilated area or utilize a dust extraction system to minimize health risks.

Tip: Always inspect your equipment before use, ensuring that it is in good working condition. Dull blades or faulty machinery can lead to accidents or inefficient results. It's also essential to secure the brick firmly in place to avoid movement during grinding, which increases the risk of injury.

Additionally, understanding the workspace is crucial. Clear out any unnecessary items around the work area to prevent trip hazards. Establishing a dedicated space for grinding also aids in maintaining focus and organization. Lastly, have a first aid kit accessible to address any minor injuries swiftly. By adhering to these best practices and safety precautions, you can ensure a more efficient and secure brick grinding experience.