FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Leave Your Message

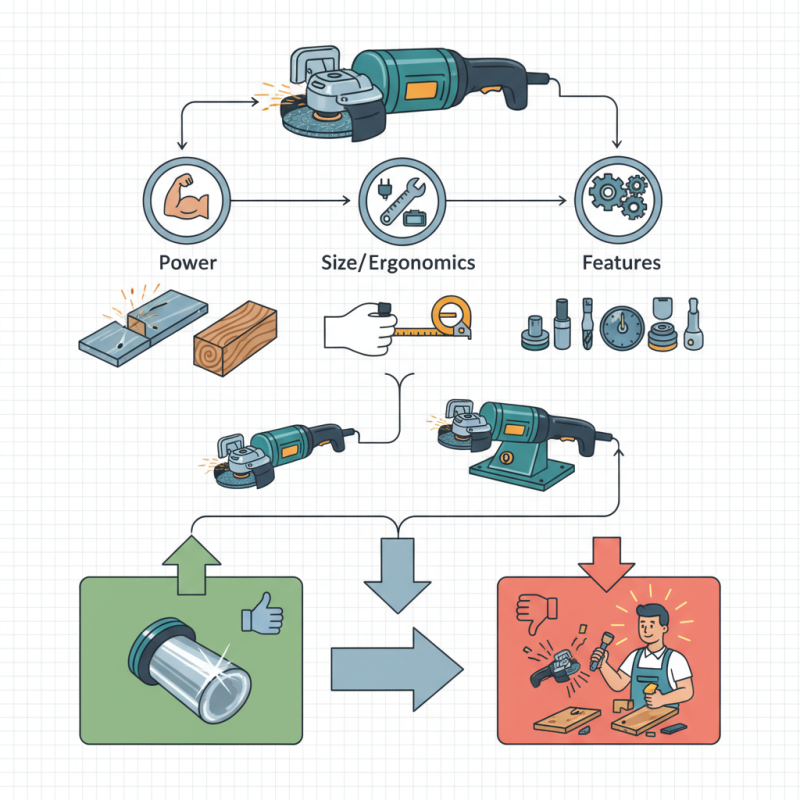

Choosing the best straight grinder is crucial for precision metalworking and DIY enthusiasts. A straight grinder can achieve clean, accurate cuts. It’s essential to consider power, size, and features. The right tool can make a significant difference in your projects.

Many users find that a straight grinder offers versatility. They can be used for grinding, polishing, and shaping materials. However, not every model performs well in all tasks. Some require more skill, while others are user-friendly. It’s important to research before purchasing.

Tools can have flaws too. Some straight grinders may lack durability or have limited speed options. Users often reflect on their choices after experiencing these issues. Selecting the wrong tool can lead to frustration. Ensuring you have the right straight grinder is vital for achieving high-quality results in your work.

Choosing the right straight grinder is essential for precision metalworking. Understanding the types available can enhance your projects. Electric straight grinders are versatile and easy to use. They deliver consistent power, making them suitable for long sessions. However, some find them heavy for intricate work.

Pneumatic straight grinders offer remarkable precision. They are lightweight, and this makes them ideal for detailed tasks. The downside? You'll need an air compressor. This setup may not suit everyone. Battery-operated grinders provide freedom from cords. While convenient, they may lack the power of their electric counterparts.

When selecting a straight grinder, consider your specific needs. Each type has its strengths and weaknesses. An electric model may be perfect for heavy-duty jobs. But for fine work, a pneumatic grinder might excel. Reflect on the tasks at hand. Balancing power and precision is crucial in the metalworking world.

When selecting a straight grinder for precision metalworking, key features are vital. First, consider the motor's power. A robust motor ensures efficiency and better performance. Look for grinders with variable speed controls. This allows you to adjust the RPM for different materials, enhancing versatility.

Ergonomics is another essential feature. A well-designed handle reduces user fatigue and improves grip. A lightweight model can simplify extended use, making it easier to maneuver. Dust collection systems can also be a plus. They help maintain a clean workspace but may not be perfect. Some grinders struggle with effective dust management.

Finally, assess the accessories included. High-quality grinding wheels or attachments can elevate your work. However, compatibility issues may arise with different models. It's important to ensure everything fits well. Reflecting on these points can lead to a more informed decision. Choose wisely to tackle your DIY projects effectively.

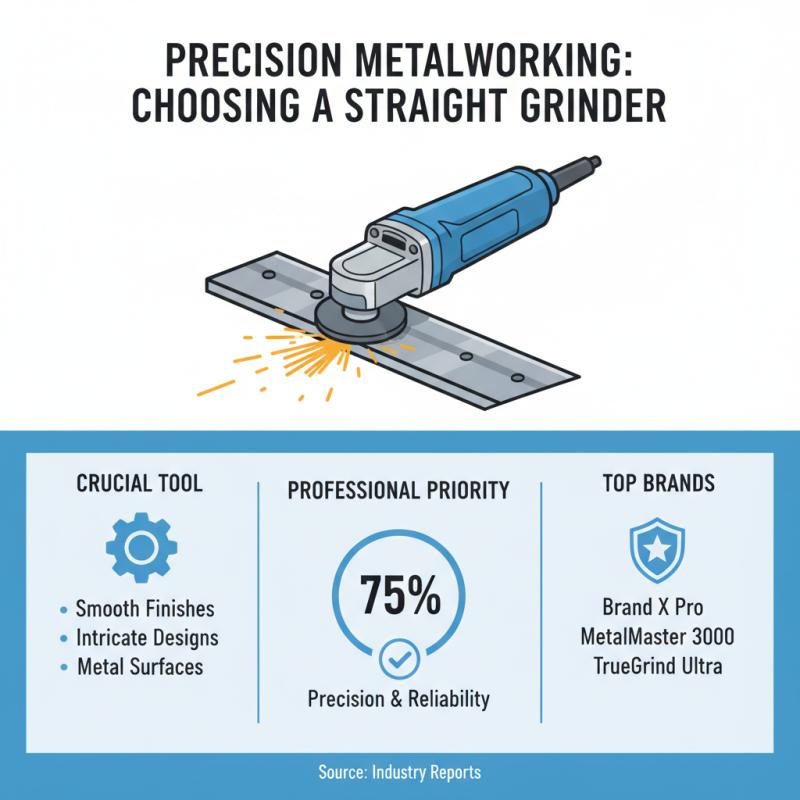

When it comes to precision metalworking, selecting the right straight grinder is crucial. Many professionals rely on top-tier brands and models for their projects. Industry reports indicate that nearly 75% of metalworking professionals prioritize precision and reliability in their tools. Straight grinders are essential for achieving smooth finishes and intricate designs on metal surfaces.

A significant factor in choosing a straight grinder is the motor power. Most industry-leading models boast motor ratings between 1 and 2 horsepower, enabling effective material removal. However, some users report dissatisfaction when tools lack adequate power for tough jobs. It's important to match the machine's capacity with project requirements.

Furthermore, user ergonomics are vital in the selection process. A comfortable grip and reduced vibration can enhance performance. Studies reveal that grinders with weighted handles reduce fatigue by 30% during extended use. Yet, there are still models that fall short in this regard. Users might find themselves grappling with discomfort, impacting precision. Ultimately, understanding the strengths and weaknesses of each model is essential for professionals seeking the best straight grinder for their needs.

When looking for the best straight grinder, performance specifications are crucial. A comparative analysis reveals key factors like speed, power, and weight. For instance, most high-performance models feature speeds ranging from 10,000 to 30,000 RPM. Higher RPMs offer better finishing on metal surfaces. However, this speed can lead to overheating if not managed properly.

Power is another critical factor. Grinders come with various wattage ratings, commonly between 500 to 1,500 watts. More powerful models are suited for heavy-duty tasks but can be cumbersome for small DIY projects. Weighing around 3 to 10 pounds, a lightweight grinder allows easy maneuverability. Yet, ultra-light models may sacrifice stability and durability during intensive use.

Pricing varies significantly across the market. Entry-level grinders typically start around $50, while advanced models can exceed $300. An analysis from industry reports shows that users often overlook long-term costs, such as replacement parts and maintenance. A more expensive model may save costs in repairs over time, yet it requires careful consideration. The balance between initial investment and ongoing expenses can be tricky for many users.

Proper maintenance of your straight grinder is essential for longevity and performance. Start by regularly checking the power cord and plug. Look for signs of wear or damage, as frayed cords can pose risks. Clean the grinder after each use. A simple wipe with a cloth can remove metal dust and debris, preventing buildup in the motor.

Pay attention to the ventilation slots, too. Keeping them clear helps in cooling and reduces overheating.

Consider lubricating moving parts periodically. Use proper lubricant according to the manufacturer’s recommendation. This habit can prevent rusting of internal components. Don’t forget to replace worn-out brushes when necessary. Ignoring this can lead to poor performance and irreversible damage. Lastly, store your straight grinder in a dry place to avoid moisture. Even a small amount can rust the tool and affect its precision. A well-cared-for grinder not only lasts longer but also performs better in your projects.